NOTE: Take great care at all times not to damage or snag the brake hose as this may subsequently make the vehicle unsafe.

DO NOT allow the calliper to hang free by its flexible hose.Remove the worn brake pads after first disconnecting the wear warning wires if these are

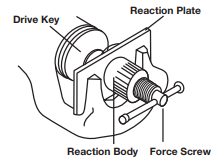

fitted. Now select the appropriate drive key to suit the piston. (The drive key should be as near as possible to the same diameter as the piston.)

Fit the drive key to the force screw (2). To make this easier, the force screw is magnetic and has two pins to engage the drive key positively.

NOTE: Some pistons need to be rewound under pressure.

For this purpose, use the reaction plate (1).

Slip the reaction plate over one arm of the T-bar on the force screw and manoeuvre it on to the reaction body so that it rests against the flange at the bottom of the body. Now fit the reaction plate into the caliper fork - see diagram - and tighten the force screw by turning the T-bar clockwise until the piston is fully rewound into the bore.

NOTE: Lubricate the force screw with a few drops of oil before using it.

Finally, loosen the force screw by turning the T-bar anti-clockwise until you can remove the force screw and reaction plate from the calliper. Fit new brake pads, service the calliper and reassemble.

In cases where only a small amount of force is needed you can use the 3/8" drive key with a 3/8" drive ratchet and extension.