Build Quality & Material Criteria for Durable Liner Pullers

Build Quality & Material Criteria for Durable Liner Pullers

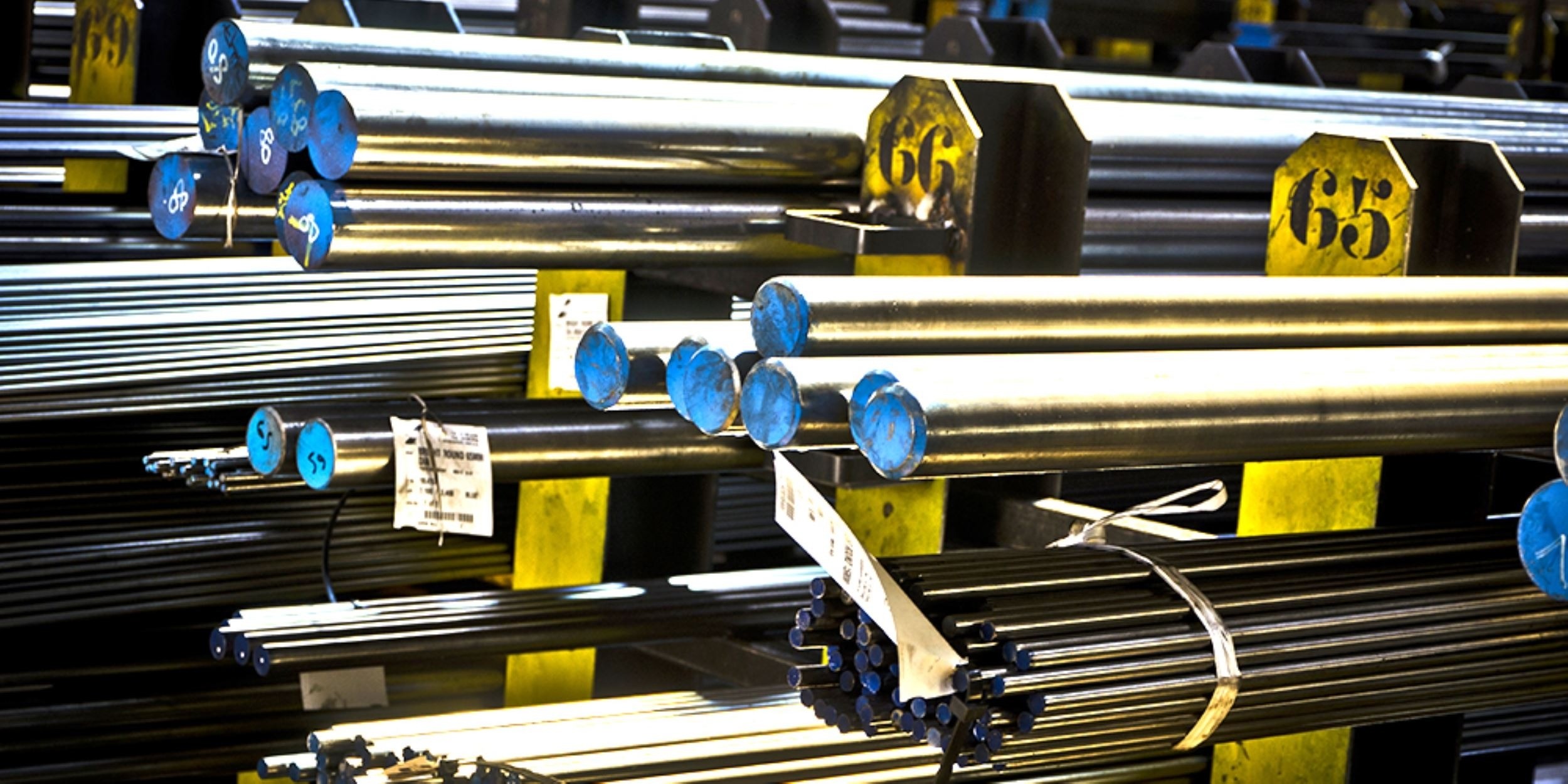

Strong materials and precision construction are essential for cylinder liner pullers that’ll withstand demanding environments. Below are key criteria drawn from industry-leading models.

45# Steel Construction (VEVOR)

The VEVOR cylinder liner puller and its pull plates are crafted from robust 45# steel, offering exceptional resistance to wear, abrasion, and impact. The kit includes thickened plates, a stable lead screw, and a durable screw nut for smoother operations.

Precision Forging & Reinforced Components

Yaqiya Group’s hydraulic puller utilizes precision-forged premium steel with powder-coated surface for ruggedness and corrosion resistance. Lead screws, support seats, and nuts are thickened to endure repeated, heavy-duty use. :contentReference

High-Grade Tool Steel (LGXSHOP)

LGXSHOP’s hydraulic puller is built from heavy-duty, high-grade steel with excellent wear and corrosion resistance—ideal for long service lifespan in rigorous conditions.

Durability Specs at a Glance

| Attribute | VEVOR | Yaqiya Group | LGXSHOP |

|---|---|---|---|

| Steel Grade | 45# Steel | Premium Steel, forged | High-grade Tool Steel |

| Surface Treatment | Not specified | Powder-coated (rust-resistant) | Corrosion-resistant |

| Component Reinforcement | Thickened pull plates | Thickened screws, seats | Heavy-duty construction |

Why DNT Tools Embodies These Standards

At DNT Tools, we manufacture liner pullers using high-grade forged steel—often exceeding 45# specs—with robust thickened components and corrosion-resistant finishes. Custom kits tailored to engine specs ensure durability and factory-level precision.