- Ningbo Dongning Tools Co.,Ltd

- Professional Chinese Tools manufacturer on hand tools& automotive tools

- Address

- No.6 Falan Rd,Hengjie Town,Ningbo City,Zhejiang,China

- Phone

- +86-574-87216625

- info@nbdntools.com

Loosen the caliper bolt heads with a ratchet. Then remove and store the rubber cap on the bleeder screw (if equipped) and loosen the bleeder screw with a box-end wrench. Reseat the bleeder screw and remove the caliper bolts.

Remove the caliper, retract the piston

Connect one end of the drain tube to the bleeder screw and place the other end in a catch jar. Then open the bleeder and force the caliper piston back into the bore with the brake pads tools(Photo 2). When you’re done, tighten the bleeder and disconnect the drain tube. Secure the caliper to the coil spring or strut with mechanic’s wire while you complete the brake job. Never let the caliper dangle by its hose.

Retract the caliper piston.Place the inboard pad against the piston and center the brake pads tool on the pad. Locate the clamp screw on the back side of the caliper. Open the bleeder and retract the piston

Next, remove the caliper bracket so you can replace the rotor. The caliper bracket bolts are quite large and are usually coated with thread locker. So you’ll need a large ratchet or breaker bar or an impact wrench to remove them (Photo 3).

Unbolt the caliper bracket.Break the caliper bracket bolts loose with an impact wrench or a breaker bar. Store the bolts and lift the bracket off the steering knuckle.

As you remove the bolts, note whether they’ve been coated with red or blue thread locker. Recoat the threads with the same type when you reinstall them.

Remove the rotor

It’s all about clean

Brake noise, vibration, harsh braking and brake pedal pulsation are the most common brake complaints, and they’re all caused by improper cleaning and installation procedures. So trust us on this point and follow all of our cleaning and greasing instructions on how to change brake pads.

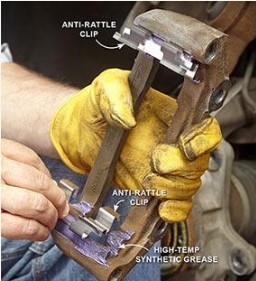

Remove the old anti-rattle clips and toss them (they can’t be reused). Then clean all the rust off the caliper bracket (Photo 5). Next, clean the caliper bolts with aerosol brake cleaner and check for corrosion. Replace the bolts if they’re corroded. Install new anti-rattle clips (Photo 6). Then grease the bolts and install new rubber boots (Photo 7).

Lube and install new boots.Apply a coat of high-temperature synthetic brake grease to the bolt and the bores in the caliper bracket. Seat new boots into the caliper bracket and slide in the greased caliper bolts until the boots seat on the bolt recess.

Then clean all the rust and debris from the wheel hub. All it takes is .003 in. of rust or crud on the hub to cause brake pedal pulsation and ruin a perfectly good brake job. So take this part seriously. Chuck a mildly abrasive polishing pad into your drill and clean the wheel hub (Photo 8).

Polish the hub.Spin the polishing pad around the face of the wheel hub. Then clean the rust off the center of the hub. Wipe off the debris and apply a light coat of nickel anti-seize to the face to minimize future rust buildup. (Don’t get antiseize on the wheel studs.)

Next, clean the new rotors. Use aerosol brake cleaner to remove the rust preventive coating. Then perform the second cleaning step shown here (Photo 9). It’s a pain, but skipping this step can also ruin your brake job.

Slide the rotor onto the hub, aligning the rotor retention screw hole with the threaded hole in the hub. Tighten the screw to specs. Next, apply the correct thread locker to the caliper bracket bolts and reinstall the caliper bracket. Apply a thin film of brake grease to the back side of the noise reduction shims, slide them into the caliper bracket and install the springs (Photo 10). Reinstall the caliper.

.

.

Add the springs.Slide the pads into the anti-rattle clips. Squeeze the pads together as you install the drag reduction springs. Make sure they go back in the same way they came out. Continue squeezing the pads and slide the caliper over the pads.

Install the wheel, torque the lug nuts, and test the brakes

Now that you’ve followed all the cleaning and greasing tips, don’t wreck your work by using an impact wrench or ratchet to tighten the lug nuts. They must be tightened to the same torque to maintain the critical rotor-to-hub fit (Photo 11). If they’re torqued unevenly, the rotor will cock slightly and you’ll get pedal pulsation.

Torque the lug nuts.Remove the jack stand and lower the vehicle until the tire just touches the ground. Set the torque wrench to one-half the specified torque and tighten the lug nuts in a star pattern. Then set the wrench to the full torque and tighten again in the same star pattern. Lower the vehicle the rest of the way and remove the floor jack.