These instructions apply to bearings in a non-drive wheel. In other words, if your car is front wheel drive, we're talking about the rear bearings. If it's rear wheel drive, you'll be replacing the front wheel bearings.

How do I know if I need new wheel bearings? Most of the time we don't even know that they need service. We just drive and never think about them. Most car manufacturers recommend a wheel bearing clean, inspection and repack every 30,000 miles.

This is usually done along with the front brake service. They need to be replaced when there is scoring and pitting or they become noisy.

What you'll need:

- Large adjustable wrench and Channelocks.

- Bearing race driver tool or various size punches.

- Socket and ratchet set or assorted wrenches.

- BFH.

- Lots of rags.

- New wheel bearings.

- Wheel bearing grease.

- New cotter pin.

- New grease seals.

- Wheel blocks.

- Safety glasses.

- A jack and a pair of jack stands.

- Rubber gloves (Optional)

Make sure that your car is parked on a level grade, rather than on any sort of hill or inclined driveway. Jack up the car and place your jack stands under the frame to support the vehicle. Block the rear wheels to prevent rolling. Set the parking brake and if you have an automatic transmission, put in Park.

In most cases you will need to remove your disc brake calipers and caliper bridge to remove the rotor. See Replacing Your Disc Brake Pads for more information on this. If your car has drum brakes, ignore this step.

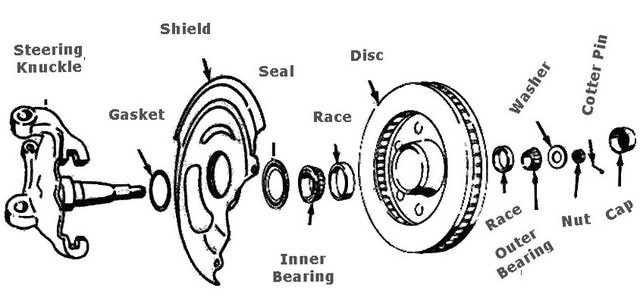

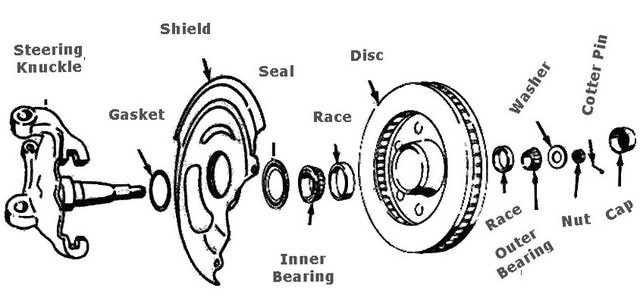

- First remove the bearing cap. This is a press fit and to remove it grab it with your Channelocks and work it back and forth until it pops off. Be careful not to crush it as you remove it.

- Once the cap is off you will see a cotter pin, Remove the cotter pin and remove the retainer ring. If your vehicle has a castellated nut, you will not have a retaining ring.

- Using your Channelocks or adjustable wrench, remove the nut from the spindle.

- Now remove the outer wheel bearing and washer and lay it aside.

- Slide the rotor or drum off the spindle. This may be difficult, but it will come off. Don't worry about hurting the grease seal; we're going to replace it anyway.

- Now that the rotor or drum is off, use a suitable tool to remove the grease seal and take out the inner wheel bearing.

- Using some of the rags wipe all the old grease from inside the hub.

- Now we need to remove the bearing races from the hub. Take a punch with a flat narrow tip and place it on the back of the race. Most hubs have gaps in them to expose the back of the race to make removal easier. Tap the race out, alternating from side to side so it comes out evenly and doesn't get cocked in the hub. Once it's out, flip the rotor or drum over and do the same for the other race.

When both races are out, clean the inside of the hub with some rags. Also make sure the spindle is clean as well. You can even use some carburetor cleaner to do a really good job of cleaning. From this point on cleanliness is important. You do not want any dirt, sand or metal chips inside the hub.