- Ningbo Dongning Tools Co.,Ltd

- Professional Chinese Tools manufacturer on automotive speciality tools,bearing puller&heavy truck tools

- Address

- No.6 Falan Rd,Hengjie Town,Ningbo City,Zhejiang,China

- Phone

- +86-574-87216625

- info@nbdntools.com

A worn-out ball joint will pivot horizontally and vertically, negatively affecting your handling at low speed, and becoming especially dangerous at high speeds. Recognizable for a knocking sound in the wheel well as you execute a turn, fixing old ball joints is an important part of keeping your vehicle road-safe. You can do it yourself for the price of the parts and the right approach.

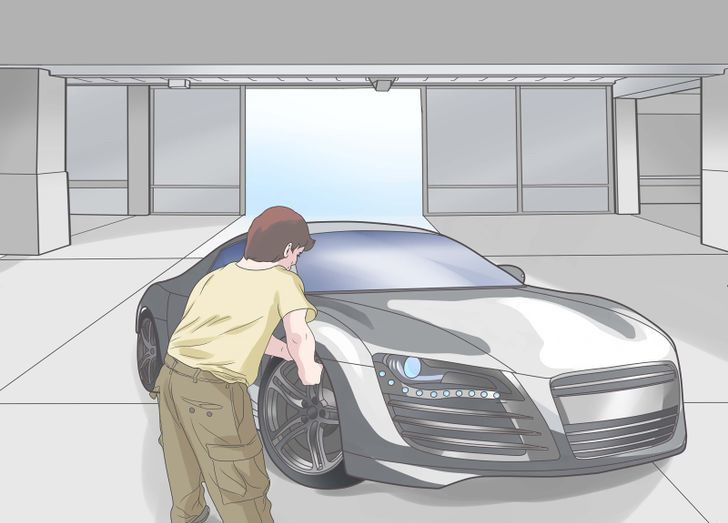

Prep the work area. Park on a flat surface and block both rear wheels, front and back. Jack both front wheels off the ground and support the vehicle with jack stands. Chock the back tires to make sure nothing will move anywhere while you're working.

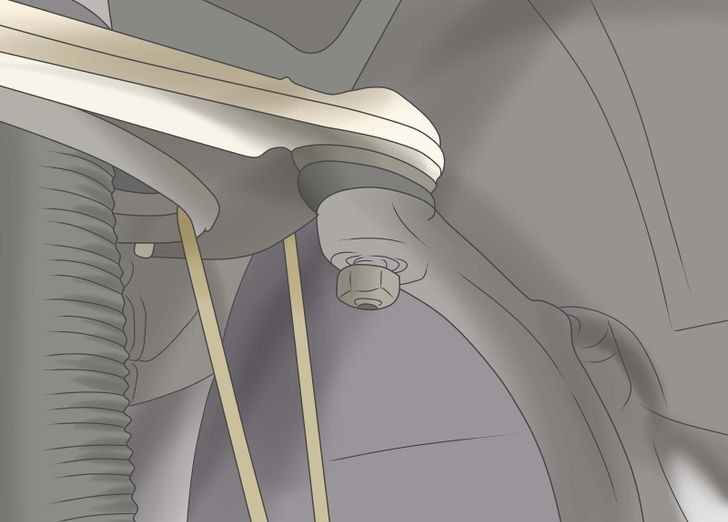

Inspect the ball joints to make sure they need to be replaced. Figure out if your vehicle's got a strut-style suspension or a control arm, then check the ball joint by either jacking up the control arm near the ball joint to check for wheel play, or by jacking up the car and using a pry-bar to check for wheel play in a strut-style suspension.

Purchase the correct replacement ball joint assembly for your vehicle. Go to the auto parts store and get a replacement part appropriate for your make and model. All you've got to know is the type of vehicle and you should be able to use the guidebook in the aisle, or ask for help and they'll be able to direct you.

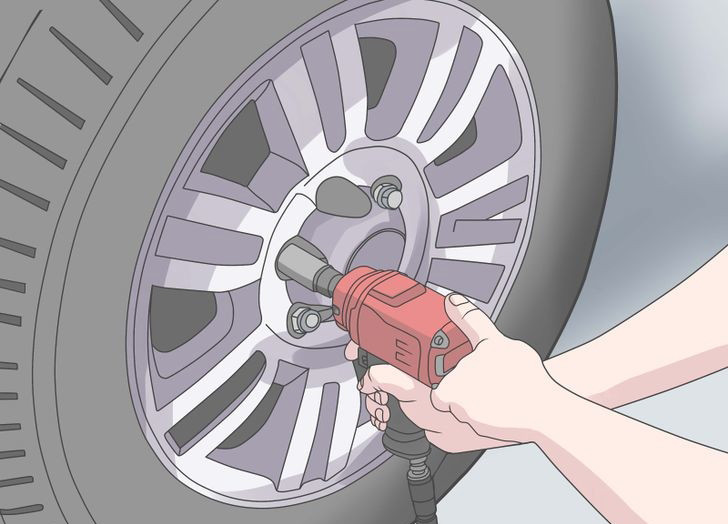

Remove the wheel and access the ball joint. Depending on the steering assembly, you may also have to move aside the brakes. If so, use a wire to hang the brakes and don’t dangle them by the brake lines. You'll also need to loosen the mounts holding the control arm or sway bar in place to give you more room to move suspension parts away.

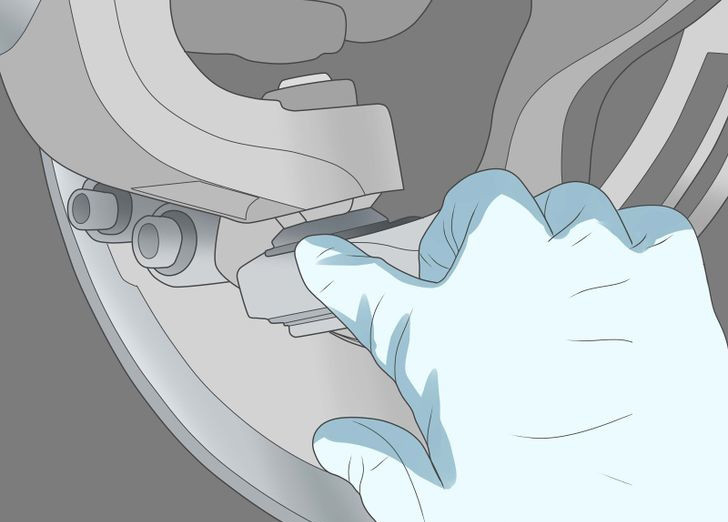

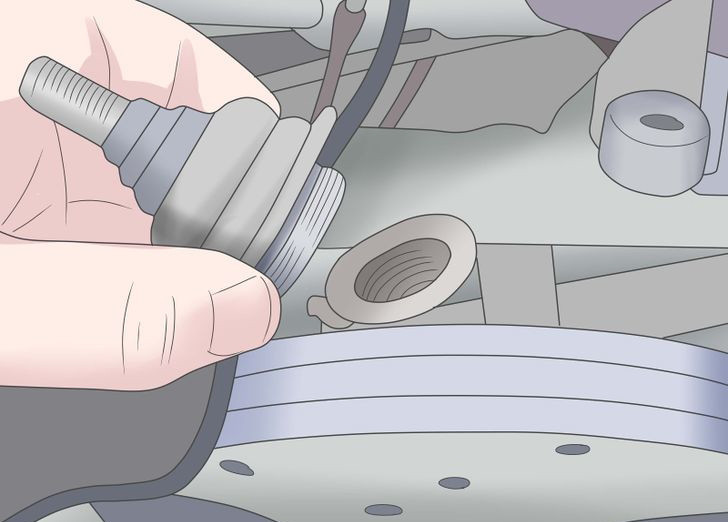

Soak all the bolts with WD-40 or PB Blaster. The ball joints can be some of the gunkiest components on the entire undercarriage, quite caked with dirt and other road grit, and it can be a bear trying to get the ball joint loose from that build-up. To make it easier on yourself, spray some metal cleaner on all the bolts to try to get them to slip off somewhat more easily.

Removing the Old Ball Joint

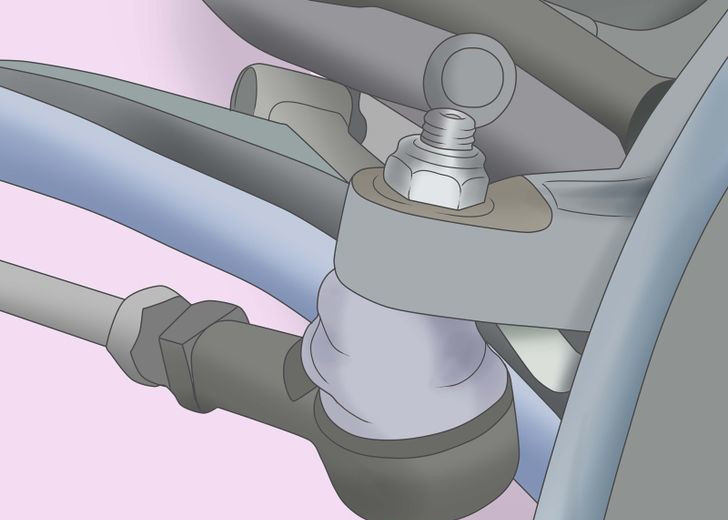

Pull the cotter pin and loosen the large castellated nut. The top should look like a crown, or castle, at the bottom. Leave the castellated nut in place, just a few turns in to keep it in a safe place.

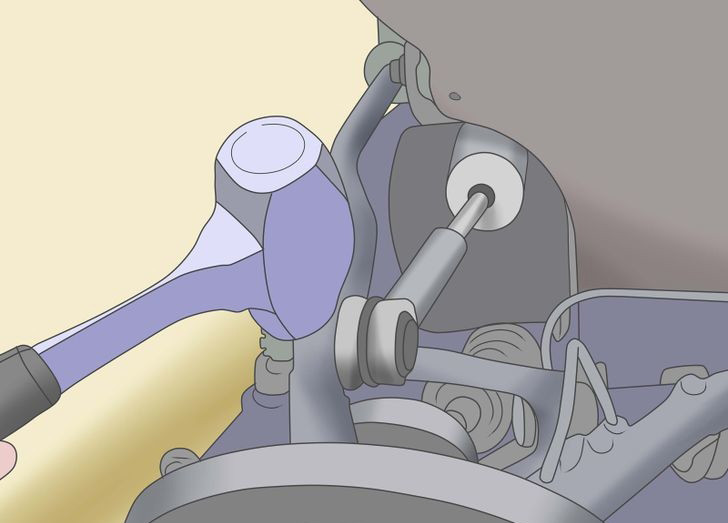

Pop loose the ball joint. The goal is to try to guide it through the hole in the upper half of the steering knuckle. It can be somewhat difficult because of the extremely tight fit which helps hold the ball joint in place and the road grime built up around the suspension, so you will most likely need to use a hammer and a special tool called a “pickle fork” or tie rod separator to get enough leverage to maneuver.

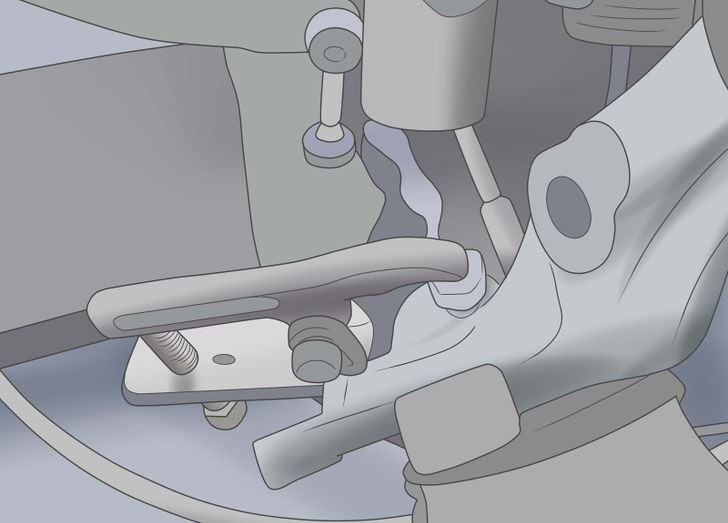

Remove the allen bolts and slide the control arm free. Loosen bolts or drill out rivets holding the ball joint in place, and slide out the ball joint. Sometimes, it's helpful to heat particularly corroded components with a torch to try to loosen them. Be careful if you try this.

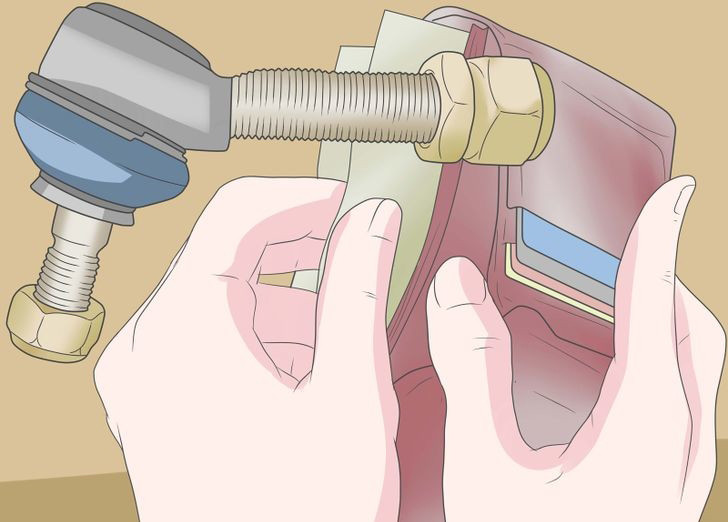

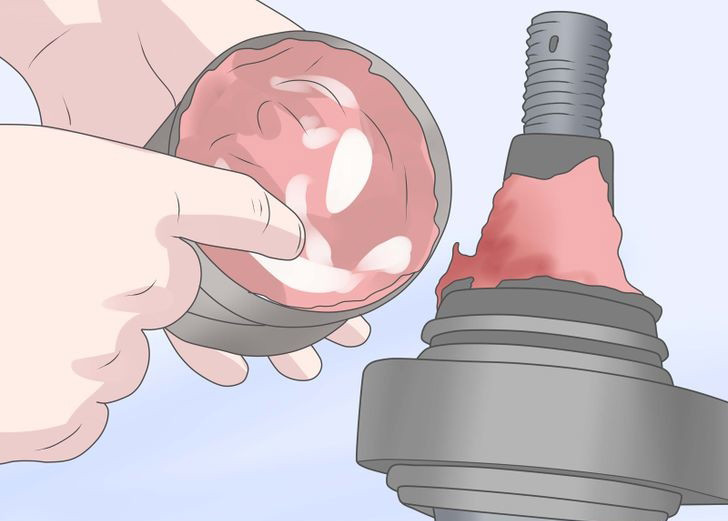

Guide the new joint through the knuckle hole. Slide the new rubber boot over the ball joint’s stud and guide the new ball joint back up through the steering knuckle hole, where it came from.

Bolt the joint into place using the hardware included. It's not usually advisable to re-use old bolts or rubber boots that covered the old ball joint, which will probably be too corroded if the ball joint wore out.

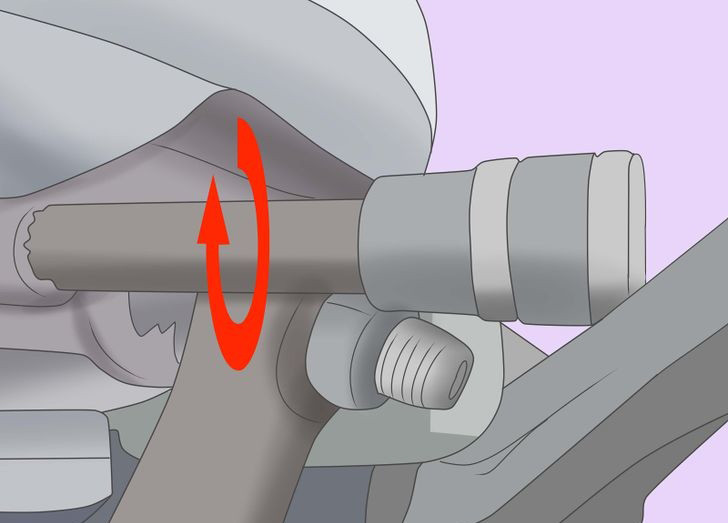

Torque the bolts to the proper specifications. Refer to the manufacturer’s service manual and use a torque wrench to tighten the bolts and castellated nut to specified levels; reinstall the pinch bolt if working on a McPherson strut.

Screw in the new grease fitting and pump grease into the assembly. If you removed the brake or wheel, reattach them and lower the vehicle back down to test out the action. Bleed the brakes, if necessary. It's a good opportunity to do any other repairs you might need to do with the brakes, since you've got them off.